The Inspection Company

Based in Hong Kong with European management, our team includes 700+ professional inspectors across Asia. We are ISO 9001:2015 certified, ISO 17020 Accredited Type A Inspection Body, Sedex and CNAS members, serving importers in more than 20 countries.

Over 25 years of experience in Asian Quality Management, we help importers, wholesalers, retailers, Amazon resellers and brands worldwide minimize risks and improve product quality.

Learn More About TICWe are a One Stop solution Quality Control Service Partner

Which Industry Do We Support?

Our Most Requested Services

- Sample Test

- Supplier Survey

- Detail Factory Audit

- Pre-Shipment Inspection

- Pre-Production Inspection

- During Production Inspection

- Container Loading Inspection

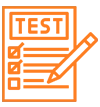

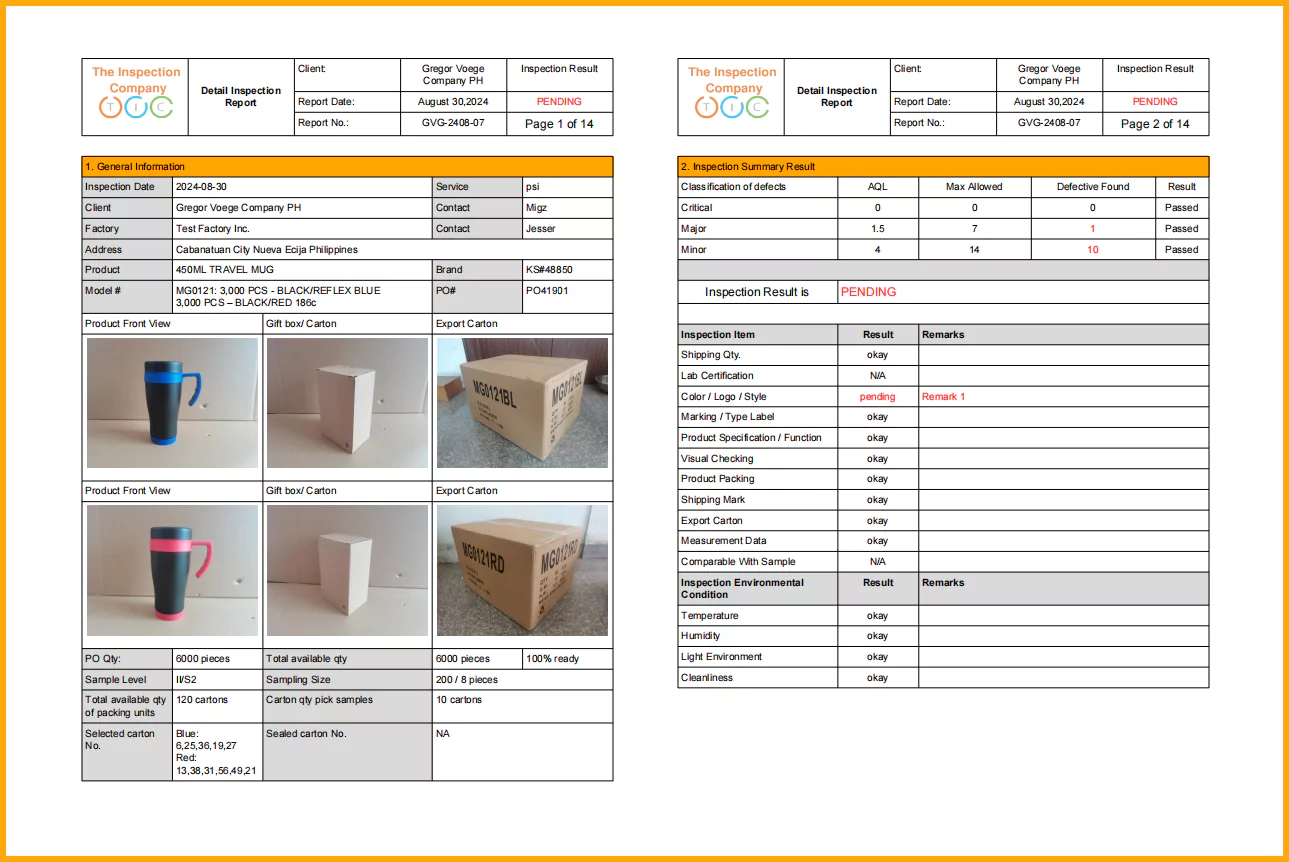

Get your free sample report

Get a firsthand look at the level of detail we provide in our product testing reports by requesting a sample.

Request Sample ReportOur Experience &

Expertise

Makes All The

Difference

Our Goal

Our goal is to improve the products made in Asia by reducing the risks for overseas purchasers and minimizing the return rate of goods to sales location.

Professional Inspectors

We have a professional team and work with companies all over the world; therefore, we cover a big range of products such as Electronics, Multimedia, Fabrics, Garments and etc.

Certification and Memberships

We are ISO 9001:2015 certified and a member of various internal organizations to ensure stable processes and procedures. We follow the intern. AQL standard for all inspections to have transparency in the results.

Since 2007

We are the Choice of Various Industries, Not Just an Option

Some Facts About TIC

25+

Countries we cover

25+

Countries we cover

with full coverage in major regions...

1000+

Satisfied Clients

1000+

Satisfied Clients

all over the world...

12000+

Audits per Year

12000+

Audits per Year

in various industries and countries...

100000+

Inspections per year

100000+

Inspections per year

with full coverage in major regions...

Convince Yourself of Our Services

Here is some feedback from our clients, about our service, which we like to share with you:Our Membership