How does TIC perform the Pre-Production Inspection?

Once you decided your vendor and finished an audit, the TIC team will come before the mass production of your order begins. The aim of the Pre-Production Inspection is to make sure your vendor understands your requirements.

Which steps does TIC follow on a PPI:

Our inspector arrives at the factory before the production starts.

Random selection of samples: Raw materials, components and semi-finished products are randomly selected to ensure the best possible representation.

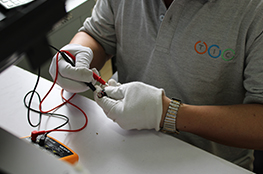

Raw materials & accessories check: The raw materials and components will be checked by our inspector according to the requirement for the product.

Product finish and workmanship check: Our inspector carefully checks the products finish, color and quality of raw materials, components and semi-finished products.

Audit of production line: Our inspector will do a simple audit of the production line, to verify the production ability, production process and quality control ability.

PPI is an early-warning system that safeguards your product against costly import risks. For all inspections, TIC uses the standard internationally recognized ANSI/ASQC Z1.4 (ISO 2859-1) statistical sampling procedure. These comprehensive criteria cover: functionality, performance, durability, overall appearance, and dimension.

Inspection report:The detail report issued be our inspector will show all findings and include many pictures for review. With this report you obtain a clear picture of whether everything is in place for tour products to be completed according to your requirements.

What Happens After a Pre-Production Inspection?

Once your Pre-Production Inspection is completed, TIC provides a detailed inspection report. This report includes:

- 📸 Photographic evidence of raw materials and factory setup.

- 📋 A checklist comparing inspected items against your product requirements.

- 📝 Notes on any non-compliance or risk areas.

- ✅ Recommendations on whether to proceed, correct issues, or delay production.

This report acts as your go/no-go decision tool to confidently approve production or ask for corrections—before any real costs are incurred.